In brief:

- The food and beverage industry faces unprecedented challenges driven by environmental shocks, uncertainty, geopolitical tensions and business cycles that favor short-term thinking.

- Building resilient and sustainable supply chains is imperative to ensuring long-term viability in the face of these challenges.

- While companies may want to prioritize immediate cost-effectiveness and efficiency, investing in resilience now can mitigate future risks and lead to mid/long-term cost savings.

- Risks vary widely across crops and regions — from climate volatility and genetic uniformity to innovation gaps and concentrated production zones — making one-size-fits-all solutions ineffective.

- Despite available models and early warnings, many companies remain unprepared for disruptions. Proactive risk assessment and early action are essential to avoid costly breakdowns.

- Procurement plays a critical role in embedding sustainability and resilience into sourcing decisions, supplier partnerships and long-term planning.

- Opportunities include comprehensive risk management, traceability and the capability to incorporate the cost implications of environmental impacts and sustainable practices into financial planning.

- The article outlines seven strategic levers — including regenerative agriculture, innovation, diversification and collaboration — that companies can use to build supply chains capable of withstanding what’s next.

The global food and beverage industry operates within a complex web of supply chains, where every product may pass through cooperatives, traders, commodity markets, manufacturers, distributors, transportation networks, retailers or direct suppliers, and more. It’s a dizzying array of entities and networks all working together to deliver products from farm to fork.

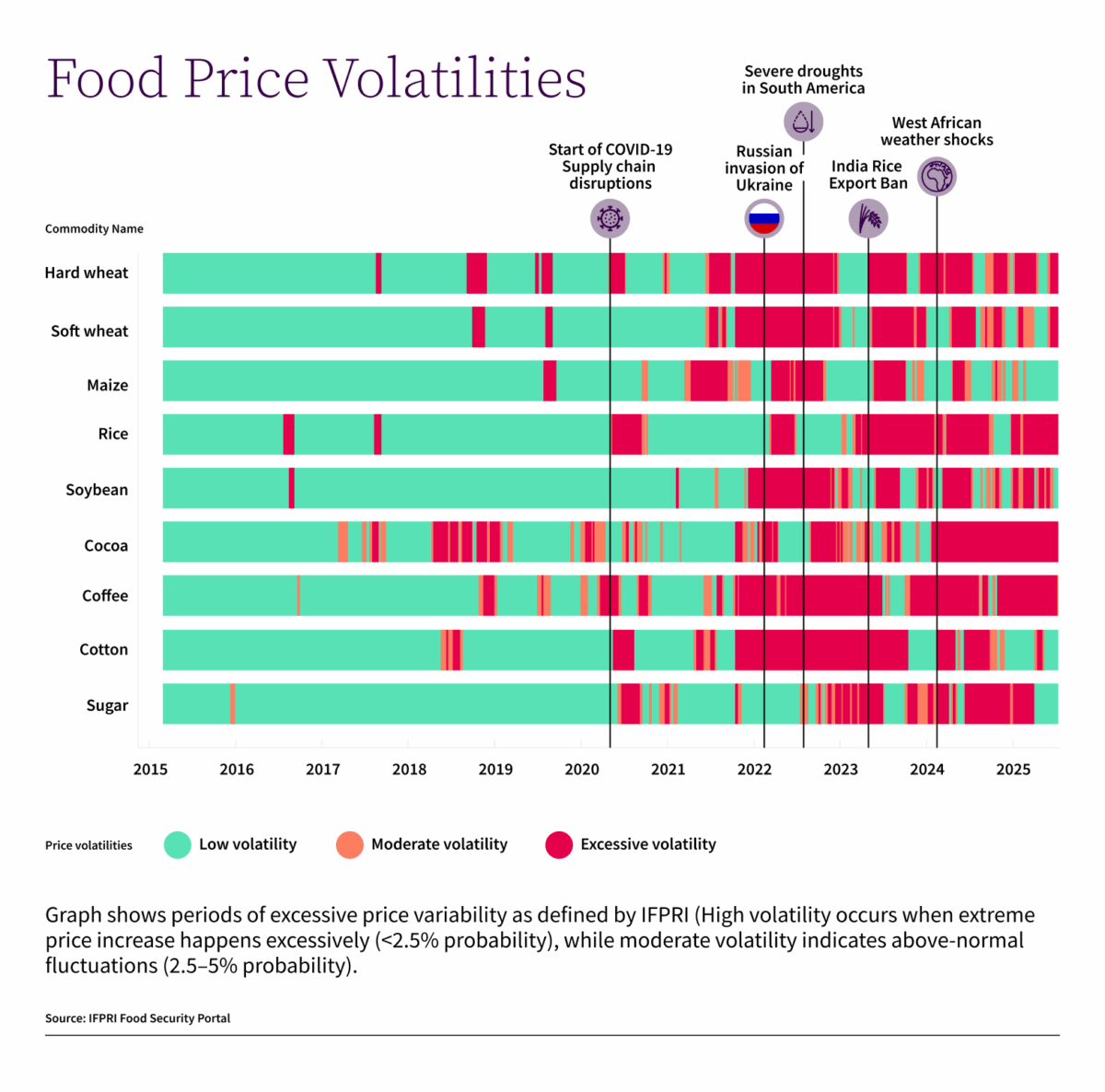

Though it may appear to function like a well-oiled machine, the supply chain faces unprecedented challenges that threaten its stability and, consequently, its ability to reliably deliver the food essential for our survival. In recent years, the fragility of the food supply chain has become increasingly apparent, driven by a combination of environmental shocks, global health challenges, trade challenges, geopolitical tensions and the difficulties of long-term planning. From global events like COVID-19 and the Russia-Ukraine war, to regional crises like European heatwaves and droughts in the Middle East, these disruptions have highlighted the urgent need for resilience.

It’s more important than ever for companies to invest in the future by building adaptive, sustainable supply chains.

Sand in the gears of our global supply chains

Operating on a global level, food and beverage companies can typically pivot to a different sourcing option if there’s a disruption with a vendor in their supply chain. But this flexibility is becoming increasingly constrained as the effects of the climate crisis make the environment more unpredictable. The geographical dependence of many commodities, particularly those from regions increasingly vulnerable to the impacts of climate change, amplifies these vulnerabilities. Commodities often sourced from the Global South and regions near the equator — such as coffee, cocoa and sugar — are disproportionally impacted by the climate crisis. In 2024, Brazil – the world’s largest coffee producer – grapples with the country’s worst drought in decades, causing the prices of several beans to increase by 55%. Cocoa prices grew 168% throughout the course of 2024 due to a supply deficit caused primarily by poor weather across key producing regions. Despite already experiencing shortages, the industry has been slow to take decisive, meaningful action to mitigate and adapt to these challenges.

Furthermore, environmental shocks and geopolitical tensions are interconnected, exacerbating the complexity of supply chain operations. Imagine a network filled with connected nodes: while the system may withstand the removal of one node, it starts to crumble when several nodes suffer disruption. The Russia-Ukraine war, for example, impacted wheat exports at a time when weather events had already limited the annual crop around the world, leading to a spike in prices and food insecurity.

While companies have adapted to small-scale disruptions with traditional risk management strategies, these are proving insufficient as major events like pandemics, conflicts and environmental crises occur simultaneously. The persistence and interconnection of these larger-scale disruptions test the resilience of a globalized industry that has long relied on short-term adaptations, such as sourcing from alternative regions.

The roadblocks to resilient supply chains

Building a resilient supply chain presents several challenges, chief among which is the need for a holistic approach to risk management that embeds sustainability and addresses both the impacts a supply chain may have on the environment and the risks that environmental disruption may pose to the supply chain simultaneously. Companies often neglect to consider broader, long-term risks such as climate change and geopolitical unrest in their short-term decision making, revealing that environmental risk assessment doesn’t factor into their purchasing decisions and plans to safeguard supply. The development of a dependable, efficient new supply chain can be a years-long process, yet companies must also maintain a focus on immediate supply gaps and costs. Such short-term concerns can inhibit companies from long-term supply chain planning.

Further complicating matters is the fact that different crops face different types of risks — there is no one-size-fits-all solution. From crops produced in highly climate-vulnerable regions (like rice facing volatility and export bans), to those reliant on concentrated production zones (like cocoa), or suffering from limited genetic diversity (like the Cavendish banana), or lagging innovation (such as potatoes under heat stress), agrifood risk archetypes vary widely and demand tailored, crop-specific resilience strategies.

Additionally, the lack of transparency and traceability pose significant challenges, particularly concerning the origin of raw materials. Companies historically have had limited visibility into their supply chains, their view often failing to penetrate beyond the immediate supplier (e.g., a commodities trader), which makes it difficult to identify and address issues at the farm level, further down the chain.

A final challenge arises when a company hesitates to focus on supply chain resilience due to short-term cost implications. Transitioning to regenerative agriculture, for example, may require significant upfront investment by farmers, and returns may only be visible after several years. The question often remains: Who should bear the brunt of these transition costs? Companies accustomed to reporting quarterly earnings may struggle to justify such long-term investments to shareholders when results can take relatively long periods of time to become apparent and are difficult to quantify.

Balancing resilience with cost-effectiveness and efficiency

How can companies balance the imperative for resilience with the relentless pursuit of efficiency that results in high profits and slim margins? This may very well be the billion-dollar question for food companies looking to build sustainable and resilient supply chains. While short-term market reactions and cost considerations often dominate decision-making, companies must recognize that investing in supply chain resilience today is the only way to ensure long-term survival in the face of environmental disruption and uncertainty.

Further, the environmental crisis is already here, with companies suffering the consequences of extreme climate events without sufficient preparation. In West Africa, for example, a combination of erratic rainfall, disease pressures and extreme weather has significantly reduced cocoa production in a region responsible for more than 60% of global supply – triggering a global shortage and sending prices to record highs. When early warning signs go unseen, companies are left reacting to disruptions instead of getting ahead of them. Failure to prioritize resilience and readiness is already resulting in significant costs, which will only multiply down the line, including supply chain breakdowns, product shortages, reputational damage and lost revenue.

Financial planning plays a pivotal role in this balancing act, as companies must weigh the immediate savings against the potential long-term costs of inaction. While investing in resilience may require significant upfront expenditures, these investments can yield long-term benefits by mitigating future risks, bolstering the resilience of agrifood systems and ultimately reducing costs over time. Some Insurance companies are even introducing specialized products designed to encourage adaptation practices, further incentivizing companies to take proactive measures.

By developing a more robust and adaptable supply chain, companies can enhance operational efficiency, improve product quality consistency, anticipate price fluctuations (to some extent), and build stronger relationships with both suppliers and consumers. These benefits ultimately create a competitive edge, positioning companies for long-term success and sustainability.

7 features of a resilient, sustainable supply chain

With time and experience, we’ve identified seven actions that build resilient supply chains, falling into two categories: tangible levers such as sustainable agriculture and portfolio diversification, and process-oriented approaches like inclusivity and collaboration. These actions can be tailored to address the diverse challenges crops face, from climate volatility to genetic uniformity and concentrated production, presenting in various cases a win-win for the farmer and the corporation:

- Integrated strategy: Procurement teams play a critical role in shaping strategies that reduce environmental impacts and build long-term resilience. Start by developing an approach that addresses both mitigation and adaptation — cutting supply chain emissions and pressures on nature, while preparing for the effects of a changing climate. This will enable you to tackle the short-term challenges of sustainability with solutions that reap returns in the long run. By integrating holistic sustainability considerations into procurement decisions, companies can better understand the complex interdependencies within their supply chains and develop comprehensive solutions that address multiple issues simultaneously.

- Inclusivity: Establish clear mechanisms for feedback and communication at every step of the supply chain to foster transparency, collaboration and accountability. Including diverse perspectives and voices in supply chain decision-making increases the likelihood of identifying potential risks and opportunities early on, leading to more effective risk management and mitigation strategies.

- Adaptability: Build agility into your operations by preparing to pivot to alternative ingredients, suppliers or regions in anticipation of and response to disruptions. Encourage innovation through new recipes and products (for example, swapping palm oil for canola where it makes sense) to maintain continuity during disruptions. This flexibility reduces risks, minimizes the impact of shocks and ensures operational resilience.

- Collaboration: In today’s era of environmental and geopolitical challenges, working in isolation can pose serious risks to business continuity. Where appropriate and legally permissible, companies should explore opportunities for collaboration — even with competitors when feasible — to pool resources, share knowledge and collectively tackle common challenges, such as drought within a shared watershed. Pre-competitive initiatives, private-public partnerships, supply chain collaborations and other joint efforts can yield substantial benefits in tackling climate, water and biodiversity challenges, leading to a more resilient food system overall. Collaboration establishes best practices, boosts supply chain resilience and fosters innovation, unlocking new market opportunities while addressing common challenges more effectively. Cross-industry coordination can also help unlock new financing mechanisms and technical support to enable smallholders to adopt adaptive technologies.

- Sustainable agriculture: Support farmers in adopting diverse regenerative agriculture practices to strengthen ecosystem resilience. One example might be to move away from monocultures, for instance with the return of dairy farmers to the old practice of grazing their cattle in apple orchards. The trees provide fruit for sale, as well as supplementary cattle feed. Not only are diversified farming systems more resilient to pests, diseases and extreme weather events, but they also improve soil health, water retention, biodiversity, and other ecosystem services while providing economic resources for the farmers. Companies can financially support and co-develop strategies at the farm level to mitigate risks and establish long-term partnerships across the value chain.

- Innovation and technology: Look to leverage emerging tools and technologies, such as artificial intelligence (AI) and remote sensing paired with geospatial analysis, to further enhance supply chain resilience. AI offers unprecedented capabilities in data analysis and predictive modeling, enabling companies and farmers to anticipate and proactively mitigate risks. Combining satellite imagery, in-soil sensors and machine learning supports precision agriculture, improves traceability and enables earlier identification of climate-related threats. Beyond tools, innovation also includes R&D in high-yield, stress-tolerant seed varieties and biotechnology to increase crop performance in a warming world.

- Portfolio diversification: Reduce reliance on specific commodities by spreading risks across different products, markets and business segments. This allows companies to offset supply chain risks associated with reliance on specific commodities or regions, reducing vulnerability to external shocks, such as climate-related crop failures or trade disruptions, and therefore enhancing resilience and stability. Chocolate manufacturers exploring vegan recipes and products is a popular current example of this strategy. In many cases, this means redesigning recipes to swap out high-risk or resource-intensive ingredients for more sustainable, resilient alternatives — without compromising taste or quality.

Investing in sustainable supply chains for a resilient future

By adopting a holistic approach to risk management, investing in innovation and fostering collaboration across the supply chain, companies can navigate the complexities of today’s changing business landscape with confidence and agility. The business case for investing in supply chain resilience is clear: Companies that act now stand to secure reduced volatility in the mid-term, business continuity in the long-term and a competitive edge, ensuring a more reliable food supply in an increasingly uncertain but persistently hungry world.