In brief:

- Macroeconomic instability is exposing risks across the global fashion industry and its supply chain. But this uncertainty also creates space for transformation and an opportunity to build resilience.

- Material innovation offers a strategic path forward by reshaping how raw inputs are developed, sourced and processed to reduce their environmental impact. This includes both next-gen and lower-impact materials, as well as improvements to the systems and processes to produce and manage them.

- Many companies are prioritizing material innovation — but often jumping straight to product concepts without clear direction. A structured approach helps avoid costly missteps and guides innovation toward measurable returns.

- To scale impact effectively, start with the basics: a science-based sustainability strategy, a clear objective and a decision-making framework.

- Equally important is driving cross-functional alignment and collaboration to shift the system. Internally, this means connecting product, sourcing, finance and sustainability departments. Externally, it means pooling demand and resources with industry peers and partners.

- Clear communication is key — and it starts with a solid, well-structured roadmap.

- Any company can unlock business value through material innovation — from reducing operational risk and driving profitability to staying ahead of evolving regulations.

Uncertainty is nothing new for fashion. The industry has always moved fast, adapted fast and reinvented fast. But today’s volatility — from economic shocks to supply chain breakdowns — is challenging even industry leaders to adapt in new ways. Facing such unprecedented times, it may be tempting to put sustainability plans on hold. But resilience isn’t built by stepping back. Doubling down on environmental action offers companies a lifeline by strengthening supply chains, securing operations and building brand trust.

With market instability on the rise, where should fashion companies focus their efforts? One lever that’s both critical and actionable is material innovation.

Material innovation is a critical lever, addressing both what materials are made of and how they’re produced. It encompasses not only next-generation and lower-impact materials, but also improvements to the systems and processes used to develop, treat and manage them. Scaling and accelerating adoption of these solutions can diversify and build new supply, localize production and reduce exposure to risk.

Material innovation includes two key categories: early-stage next-gen materials and commercially available lower-impact materials.

- Next-gen fibers and materials: Novel, innovative solutions with the potential for improved environmental and/or social outcomes compared with conventional options. These are typically in early stages of development or commercialization and require further technological advancement and cost optimization for widespread adoption. The long-term goal is for these materials to transition into lower-impact solutions as they mature.

- Lower-impact fibers and materials: Established solutions that consistently deliver reduced impacts and increased benefits for climate, nature and people compared to conventional alternatives. These materials are commercially established and technically compatible with existing supply chains, though systemic challenges like pricing and supply chain integrity still need to be addressed to enable broader scale.

Source: Scaling Next-Gen Materials in Fashion: An Executive Guide, BCG & Fashion for Good

The need for progress on material innovation is urgent. Raw materials drive a significant portion of fashion’s environmental footprint — but solutions are already within reach. Lower-impact options are available today and primed for adoption, while many next-gen materials are ready to scale. Improvements to production processes also offer immediate opportunities for impact reduction.

As geopolitical and economic uncertainty stall broader decarbonization, lower impact materials offer a more stable, lower-risk path forward. Acting early builds a competitive edge, strengthens resilience and signals serious climate and business leadership.

The financial case is just as strong. Scaling next-gen materials could unlock up to a 6% net profit increase by enabling access to alternative, sustainable and locally sourced raw materials. It’s not just about reducing fashion’s environmental footprint — it’s a strategic opportunity to reshape supply chains and deliver business value.

But there’s a catch. Without the right foundation, material innovation can become a liability. Too often, companies begin with a product concept, chasing innovation without a clear direction. What looks promising on the surface can fall short if it isn’t grounded in a strong strategy and longer-term roadmap. To avoid costly detours, companies need clearly defined targets for recycled, lower-impact and alternative materials — and a plan to integrate lower-impact options into their overall material strategy.

With so many trade-offs to consider, it’s natural to feel stuck or overwhelmed. The good news: There are clear steps to set lower-impact material strategies up for success — and help the industry turn a corner on supply chain transformation.

Step 1: Start with your sustainability strategy

Before diving into material innovation, it’s essential to start with the bigger picture. Your material strategy shouldn’t exist in a vacuum — it needs to be grounded in your company’s overarching sustainability strategy.

This strategy should define top-level environmental goals across impact areas like carbon, water, land use and biodiversity. A robust materials strategy stems from understanding where your biggest hotspots are and what targets you’ve already committed to addressing.

When companies skip this step, they risk chasing promising material innovations that don’t actually move the needle — or worse, create unintended impacts elsewhere. Knowing your company’s highest-priority issues sets the foundation for focused, high-impact outcomes.

Step 2: Define your objective + budget

Once your company’s overarching sustainability strategy is in place, you can define specific objectives for your material strategy. It’s essential to take a holistic approach, considering multiple impact areas rather than focusing on a single metric.

Once your objective is set, determine your budget and consider how to derive the greatest ROI. This cost-benefit lens is critical. Starting “too small” can mean missing high-impact opportunities. Starting “too big” can lead to over-investment and premature scaling.

For example, imagine 25% of your company’s sustainability budget is allocated to material innovation. Should you use it to launch a capsule collection that may not scale? Or invest that same amount into piloting a fiber with dramatically lower water or chemical use? Another option might be upgrading dyeing processes to reduce energy demand and eliminate harmful effluents.

The answer isn’t always straightforward. The right path depends on your business priorities. Taking a zoomed-out view that considers both short- and long-term outcomes helps set a clear, strategic direction from the start.

Step 3: Set your strategy + decision-making framework

Once priorities and objectives are set, they need to be backed by a comprehensive materials strategy that’s driven by a science-informed decision-making framework. It’s easy to be swayed by compelling startups or headline-grabbing prototypes — but investment decisions must be grounded in your objectives and sustainability targets.

Not everything that looks innovative delivers meaningful results. That’s why your materials strategy must be aligned not only with your objectives, but with science. A robust framework can help you navigate trade-offs and de-risk decisions, ensuring you invest in solutions that align with your goals — and avoid those that create unintended consequences that undermine your investment.

Take the example of a footwear brand weighing conventional leather against a fruit-based alternative. While the fruit-based material uses fewer chemicals in the dyeing process, it requires a polyurethane resin coating, making it non-biodegradable. And although it’s plant-based and natural, the process of transforming these fibers into a leather-like material is energy intensive. In this case, switching materials might not be the first move. A better opportunity may lie in exploring innovation in the conventional leather’s tanning process.

This illustrates a key, but often overlooked, point: Innovation can exist in both product and process.

Material selection inevitably involves tradeoffs. A climate benefit might come with a water or land-use impact, for example. Life cycle assessments (LCAs) are a valuable tool, but not the whole story. A comprehensive decision-making framework should go beyond standard indicators to include factors like land-use change, deforestation risk and labor concerns.

It also needs to reflect where a solution is in its development curve. Early-stage innovators can’t be measured by the same KPIs as established suppliers — like cost per unit or immediate scalability. These materials often aren’t “ready for business” on day one. That’s why some companies choose to support them through innovation hubs or spin-offs, where they can grow outside the constraints of conventional supply chain metrics.

Some companies have had to completely rethink their materials strategy after investing in early-stage concepts without realizing that manufacturing were undermining their climate goals. In cases like these, premature investment in isolated product concepts leads to wasted time and budget — leaving companies stuck in the pilot phase with no clear path to scale.

To guarantee success, businesses must implement a decision-making framework that takes a big-picture approach, aligning their materials strategy with both corporate priorities and supply chain realities. Bringing in a third-party as an innovation partner can support companies on how to map out this framework from a bird’s eye view, connecting the dots across all necessary business operations.

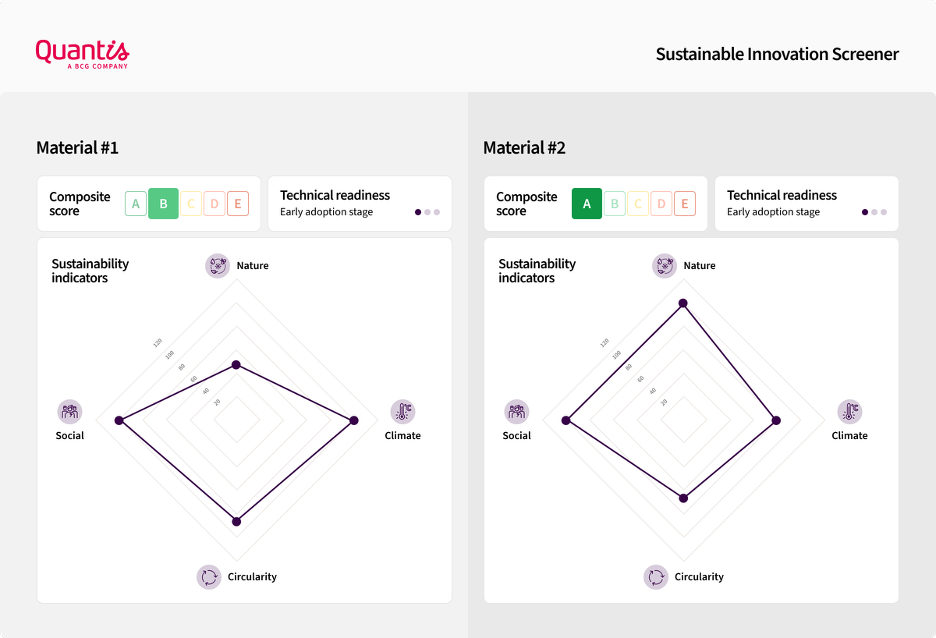

Innovation dashboards, like the Quantis example above, are especially useful for comparing materials side by side. They give brands a clear view of trade-offs across impact areas. In this example, Material #1 has a weaker score on nature, while Material #2 performs worse on climate and circularity. But its strong performance on nature lifts its overall score slightly higher.

Step 4: Align individual + collective responsibilities

As with any sustainability initiative, executing a material innovation strategy requires both individual and collective effort.

At the company level, they must be integrated across business functions with interconnected metrics — not siloed within the sustainability team. Finance, design, product development, merchandising and sourcing all need to sit at the table. In particular, product designers play a critical role. If they’re not engaged early and empowered to experiment, the investment is unlikely to yield returns. Designers are the gatekeepers of what gets made — without their buy-in, next-gen materials won’t make it past the drawing board. When there’s company-wide alignment, material innovation can become a long-term business goal backed by shared accountability and incentives.

According to the latest report by BCG and Fashion for Good, Scaling Next Generation Materials: An Executive Guide, companies must take on both individual and collaborative actions in areas related to demand, cost and capital.

From a collective standpoint, brands must be intentional about pooling demand and sharing resources with other brands. With such a fragmented yet interconnected network within the global supply chain, progress depends on collaboration — with stakeholders, suppliers and even their competitors. Regardless of size, no single company can transform the system alone.

To scale the adoption of lower-impact materials, brands can co-develop fabric specifications, share financial risk and commit to common suppliers. In practice, this could mean forming pre-competitive consortia to pool demand and standardize requirements, giving manufacturers the confidence to invest and scale. These partnerships can unlock system-wide efficiency, paving the way for accelerated innovation.

Successful partnerships also depend on trust. Many startups and supply chain partners are cautious about sharing their data to protect intellectual property. Bringing in a neutral third party can help ensure fair representation, build trust and facilitate productive agreements. An external partner can also help brands navigate the sensitivities around transparency, easing communication and helping create conditions for effective collaboration.

Step 5: Establish clear + effective communication

Clear communication is critical to the success of any material innovation strategy — and it starts with a strong foundation: a defined objective, a science-based strategy, a decision-making framework and a clear roadmap of actions.

Internally, communication enables cross-functional alignment and decision-making around investment and funding. Externally, growing regulatory pressure, such as the Ecodesign for Sustainable Products Regulation (ESPR) and environmental labeling requirements, is raising the bar on transparency. Companies will need science-based evidence to back up material claims and avoid greenwashing risks. Building a credible narrative from the start is essential.

But communication without structure will miss the mark. A well-structured material innovation roadmap gives teams what they need to communicate effectively across and outside the business.

Everyone can help build industry resiliency through material innovation

No matter how big or small, every company can contribute to material innovation — and, in turn, help build resilience across the industry through localized production, diversified supply and reduced risk exposure. Even small-scale actions, when strategically aligned, can support meaningful progress.

More important than the size of the investment is the quality of the effort. When a company’s objective, strategy and decision-making framework are established, any contribution can be optimized to yield meaningful impact, both individually and collectively.

With economic uncertainty and ever-evolving regulations, like the rules on recycled content and recyclability, companies need to start building resilience now. A strong foundation ensures the material innovation approach is both credible and business-aligned — equipped to stay on course and deliver lasting value.