Quantifying the plastic leakage of an outdoor jacket across its life cycle

To identify effective solutions to tackle plastic leakage along the life cycle of its products, Sympatex teamed up with Quantis, eco-design center EA and the Plastic Leak Project to quantify the leakage of a new outdoor jacket.

Challenge

Sympatex Technologies is a leading global supplier of high-tech functional materials in clothing, footwear, accessories and technical fields of application. The company has actively been working through research and partnerships to reduce the environmental footprint of its products, and has made ambitious commitments to achieve 100% circularity and eliminate microplastic pollution from occurring over the lifetime of its functional textiles.

A key challenge Sympatex has faced in achieving this goal is the lack of clear information on the sources and amount of plastic leakage occurring across the life cycle of its products. Sympatex joined the Plastic Leak Project (PLP), co-founded by Quantis and eco-design center EA, to fill this knowledge gap.

Insights

Growing awareness around the environmental impact and scale of plastic pollution has spurred many companies to tackle plastic leakage in their value chains. Yet they lack the necessary information and tools to transform these commitments into meaningful actions. Currently life cycle assessments, a key tool companies use to assess the environmental impacts of their products and business, do not account for plastic as a pollutant, meaning businesses can’t identify when or where plastic leakage is occurring.

Designed specifically for business, the PLP guidelines are the first science-based methodology for calculating and reporting estimates of plastic and micro-plastic leakage across the value chain — including leakage that occurs as a result of product washing. Sympatex was one of the first companies to pilot the Project’s pioneering methodology, performing a plastic leakage assessment exemplified by a three-layer hardshell jacket.

Actions

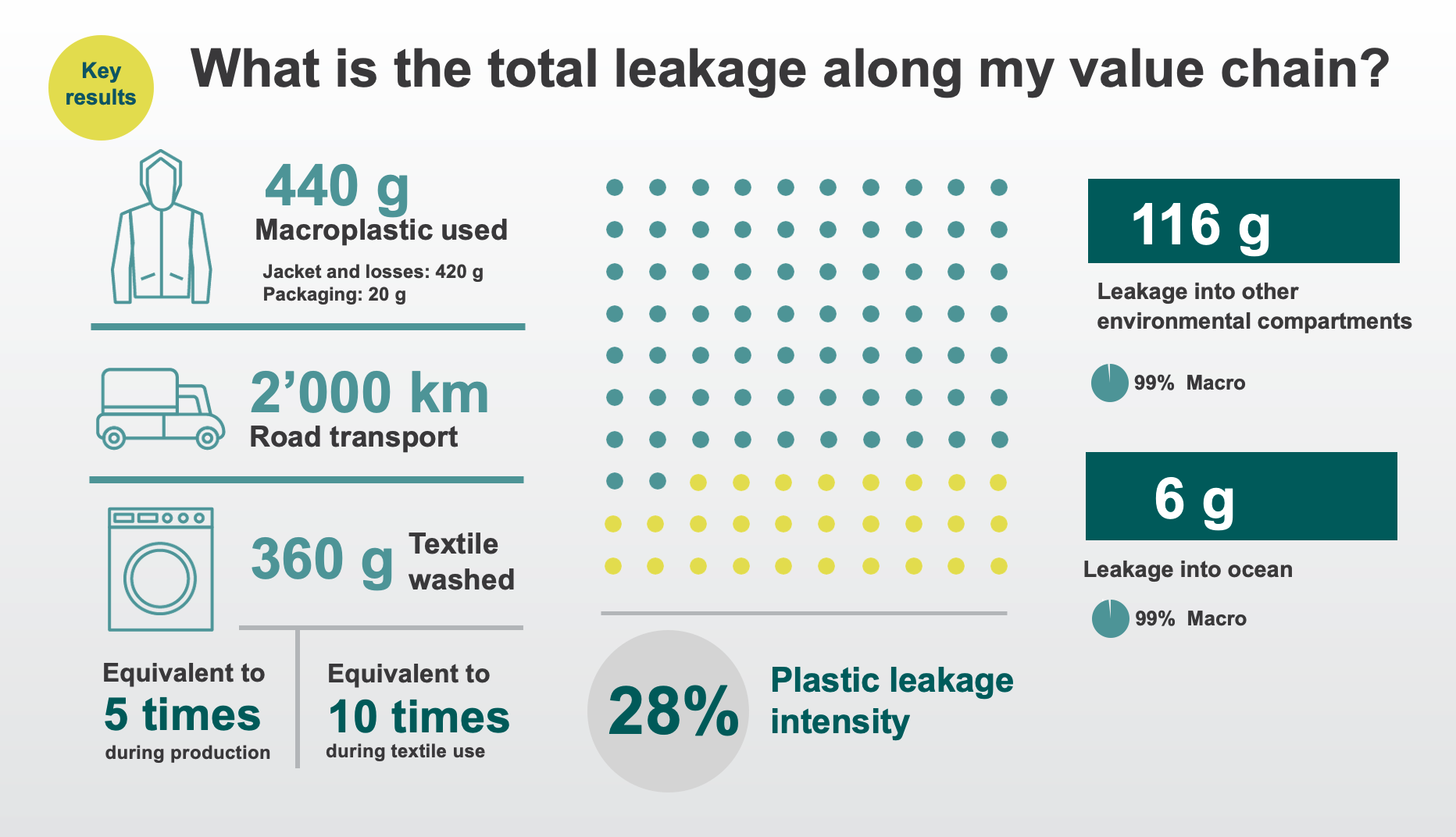

As a first step, Sympatex collected data about the amount of plastic used across the value chain to produce the polymer in its hardshell jacket — from production all the way through to use (washing) and disposal. Applying the PLP guidelines to Sympatex’s data, Quantis then identified the total plastic leakage linked to the hardshell jacket, where the leaked plastic ended up in the environment, as well as the contribution of each life cycle stage and geographic region to the overall amount of leakage.

Impact

The results of the assessment revealed that 28% of the plastic used across the life cycle of the jacket leaks into the environment. Approximately 99% of this leakage was found to occur not during use phase (washing of the product), as it is commonly assumed, but rather at end-of-life. At this stage, the leakage is due to inadequate waste collection and treatment systems in developing countries where 50% of the used apparel is estimated to be exported to give them a second life.

Learnings

The perception of the use phase as the most impactful stage in terms of plastic leakage because of shedding during washing is prevalent. The findings of Sympatex’s assessment show that end-of-life can be more impactful than the use phase, and greater efforts and investment should be directed towards finding ways to prolong the lifetime of apparel as well as to improve the waste management systems in developing countries where a lot of apparel ends up at the end of life.

Areas of expertise

Sector

Project Manager

Laura Peano

Senior Sustainability Consultant

“The results of the assessment really surprised us and broke down some misconceptions about where in our value chain plastic leakage is occurring. We now know where we need to be focusing our efforts in order to have a real impact in eliminating plastic pollution from the life cycle of our product. At the same time, it confirms us in our ambitious goal, which we have set for ourselves, of closing the textile loop as quickly as possible.”

Dr Rüdiger Fox, CEO

Sympatex

Latest case studies

Case Study

Accor

Quantis supported Accor, a world leading hospitality group, to develop a new methodology to ensure the accuracy of Accor’s emission calculations while simplifying both the data collection process and making it possible at hotel level.

Case Study

Manzanita Capital

Quantis supported Manzanita Capital, a private equity fund specializing in luxury and premium niche beauty companies, to guide their portfolio companies towards a more sustainable future.

Case Study

Pharma Company

Quantis supported a global pharmaceuticals company in understanding its impacts and dependencies on nature, assessing the related risks and opportunities, and evaluating the need for an overarching biodiversity strategy.